ABOUT THE CENTER

The Plasma Center has been established at the Biotechnical Faculty, University of Ljubljana, May 27th, 2019. The activities are coordinated by the head of the center, Assist. Prof. Sebastian Dahle, and the steering board of four professors at the faculty.

The topics covered by the center are addressed by members all over the faculty. The activities further include collaborations inside and outside the university.

Head of the center

Assis. prof. dr. Sebastian Dahle

Tel.: 01 320 36 18

E-mail:

Plasma technology is innovative and environmentally friendly. Plasma processing offers a variety of possible applications. The main areas of the Center's operations are further development of plasma technology, the development of new applications, and the implementation of joint research and development projects with industry partners and academic circles.

The topics include, among others:

- Surface treatments of surfaces of various materials and composites for further processing, such as coating, bonding or producing composites,

- Deposition of coatings on various surfaces,

- Removal of contaminants and impurities from surfaces,

- Purification of gases, i.e. removal of pollutants and inactivation of allergens and pathogens,

- Processing of value-added gases in chemical and process engineering,

- Wastewater treatment,

- And many more.

The center provides a common basis for all activities in the field of plasma applications at the Biotechnical Faculty.

The activities of the Plasma Center include:

- Establishment of collaboration between researchers, academic teachers and technical staff within Biotechnical faculty, as well as at other faculties of the University of Ljubljana and from other institutions,

- Support at preparation of project proposals, so on the national and European level, as well as globally,

- Support at various plasma applications by offering the infrastructure.

RESEARCH EQUIPMENT

I. DIRECT TREATMENTS WITH DBD PLASMA

Plasma surface treatments are utilized in various industries. In particular, non-thermal plasmas can be used to process all types of materials, including metals, glass, ceramics, polymers, and bio-based materials. The two most common non-thermal plasmas at atmospheric pressure are Corona and dielectric barrier discharge (DBD) plasmas. The latter demonstrates better flexibility, ease of implementation and the widest range of applications. Figure 1 and Figure 2 show the two most common examples of conventional DBD plasmas for surface treatment.

Figure 1 shows the discharge on a metal plate with filaments formed in the air at atmospheric pressure. This is a typical pre-treatment for gluing and similar applications.

In Figure 2, the arrangement of the filaments does not depend on the thickness of the work piece, because the work piece is placed at a floating potential, which is affected by both HV electrodes. As shown in the figure, the DBD floating electrode approach (FE-DBD) allows both HV electrodes to be placed on the same side of the work piece. Thus, the machining process is mostly independent of the thickness of the work piece. The picture shows an example treatment of a wood substrate.

External link to  Open in new window

Open in new window

Figure 1: Direct dielectric barrier discharge (DBD) in the case of metal plate processing.

External link to  Open in new window

Open in new window

Figure 2: Dielectric barrier discharge with floating electrode (FE-DBD) in the case of wood processing.

II. SURFACE DISCHARGE PLASMAS

DBD direct discharge applications are limited to either metal or thin non-conductive work pieces. In the case of surface discharge plasmas, both HV electrodes of opposite polarity are in the same dielectric matrix, where their position near the matrix surface allows the electric field to extend outwards and establish a plasma discharge right on the surface of the electrode. Further variants of surface plasma setups place one grounded electrode on top of the matrix or both electrodes on opposite sides of the dielectric material. In essence, the functionality is the same for all the described variants or layout options.

Figure 3 shows an example surface plasma that can be used for surface treatments. The presented smaller device is suitable for preliminary studies in the laboratory. In contrast to the smaller device in Figure 3, Figure 4 shows a larger device suitable for machining larger work pieces on a conveyor belt.

External link to  Open in new window

Open in new window

Figure 3: Small electrode plate with purple surface plasma in air.

External link to  Open in new window

Open in new window

Figure 4: Equipment for processing various materials with a surface discharge plasma, which is placed above a conveyor belt.

III. REMOTE PLASMA

Plasma discharges can also be established as indirect, local treatment of the substrate. This is also called a remote plasma, as the plasma excitation occurs inside the tool, whereas the reactive plasma gas is blown out of the device through an opening or nozzle at the bottom of the device. In this case, the machining is independent of the work pieces‘ dimensions and it allows machining of profiled surfaces and within surface structures.

A) DBD JET

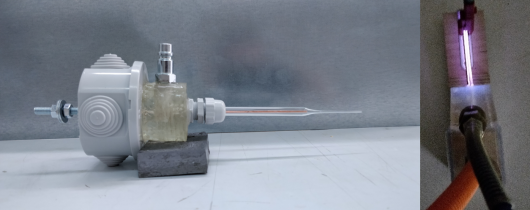

DBD discharges are suitable for plasma jet placement as shown in Figure 5. On the left is a photograph of one embodiment of the device with a DBD jet, on the right is a photograph of a DBD jet in use.

Figure 5: DBD plasma jet: model device (left) and during plasma operation (right).

B) GLIDING ARC JET

Another possibility to operate a plasma jet is thermal discharge, such as a gliding arc. Although the arc is a thermal discharge, the plasma jet of the gliding arc does not burn the work pieces’ surfaces even of organic matter. In Figure 6, a gliding arc jet on a CNC positioning system (left) and a plasma jet treating a wood substrate within a digestorium chamber (right) are shown.

Figure 6: Gliding arc plasma jet for surface treatments on a CNC positioning system (left) and a similar plasma jet during the treatment of a wooden substrate in digestorium chamber (right).